Customer:

We would have our hypothetical customer, which is "ABC Retail," a mid-sized company specializing in selling clothing and accessories online. ABC Retail is a company having one large warehouse that serves at the center of their distribution network. It faces seasonal peaks around holidays and also needs to deal with multiple inventory items of thousands of SKUs. For this purpose, they adopted warehouse inventory tracking software to keep everything in check.

A Challenge to Create a Warehouse Inventory Management System for Warehouse:

Manual inventory management system for warehouse through ABC Retail caused several problems:

- Inaccurate Inventory Tracking: Because of data entry errors from manual inputting; there was an inaccuracy in the record, leading to stockouts and overstocking and frustrated customers.

- Ineffective Warehouse Operations: Finding items was laborious and not very effective. Without an evident put-away strategy and an optimized picking route; labour hours were wasted.

- Failure to meet orders: Due to the mismatch of inventory at peak season; it failed to ship orders and even lost some sales due to processing delays.

- Poor real-time visibility: It is not very easy for management to have proper and clear views of the inventory levels. As such; decision-making on purchasing, pricing, and promotions could be challenging.

- Complex Reporting: The stock reports were very time-consuming and tiring to prepare, which limited the possibility of analysis and planning.

Warehouse Inventory Tracking Software Implemented By Our Team:

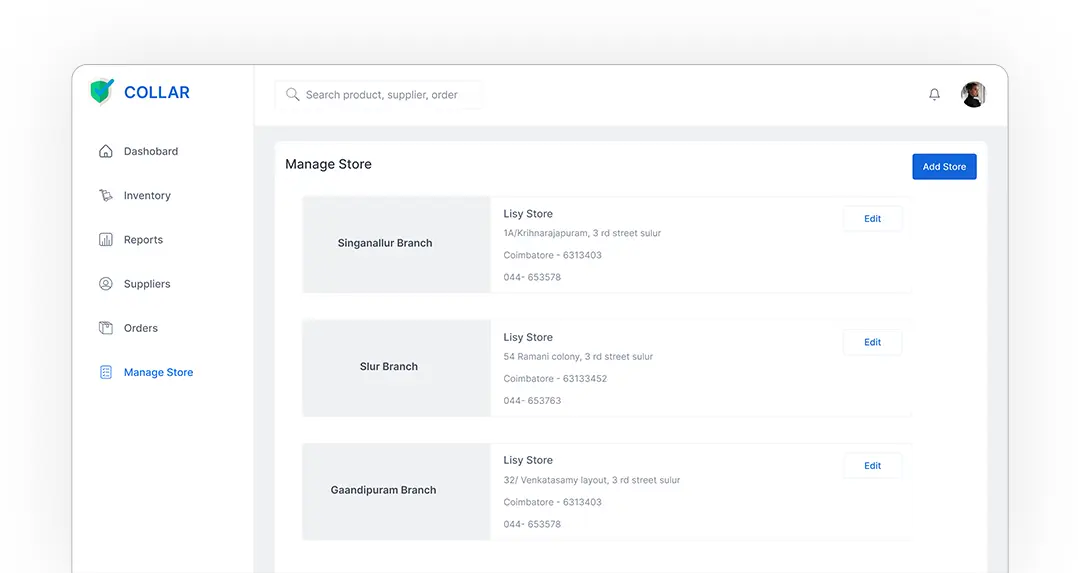

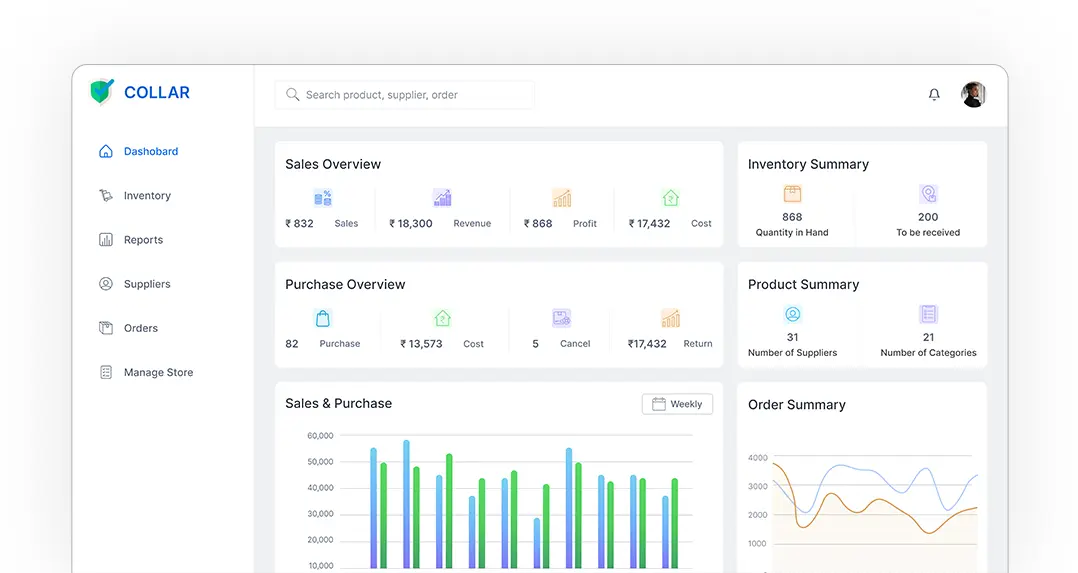

WIMS Retail implemented an all-inclusive inventory tracking software for small businesses to address the challenges described above. The system contained the following vital elements:

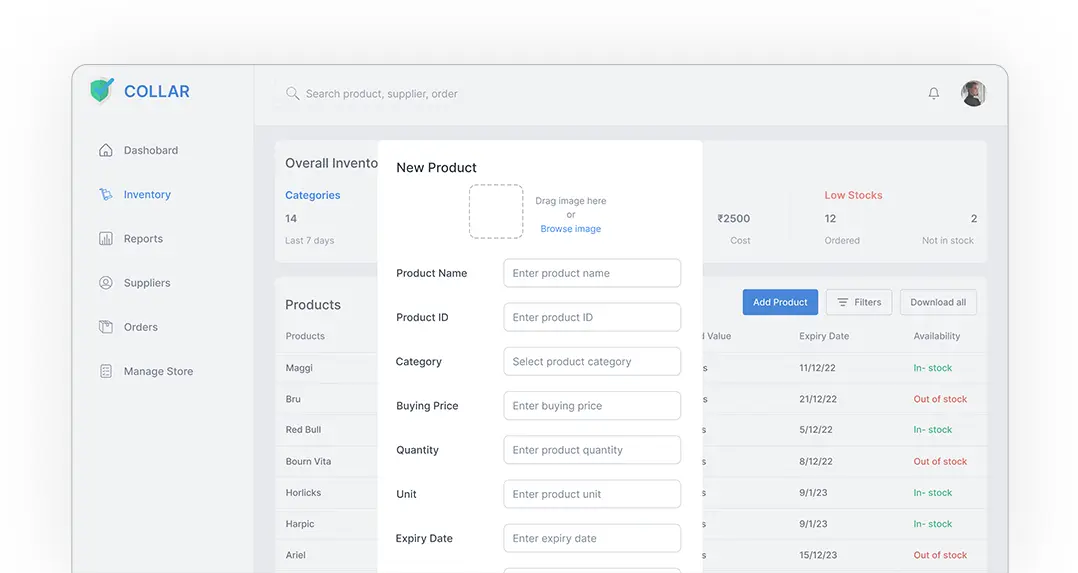

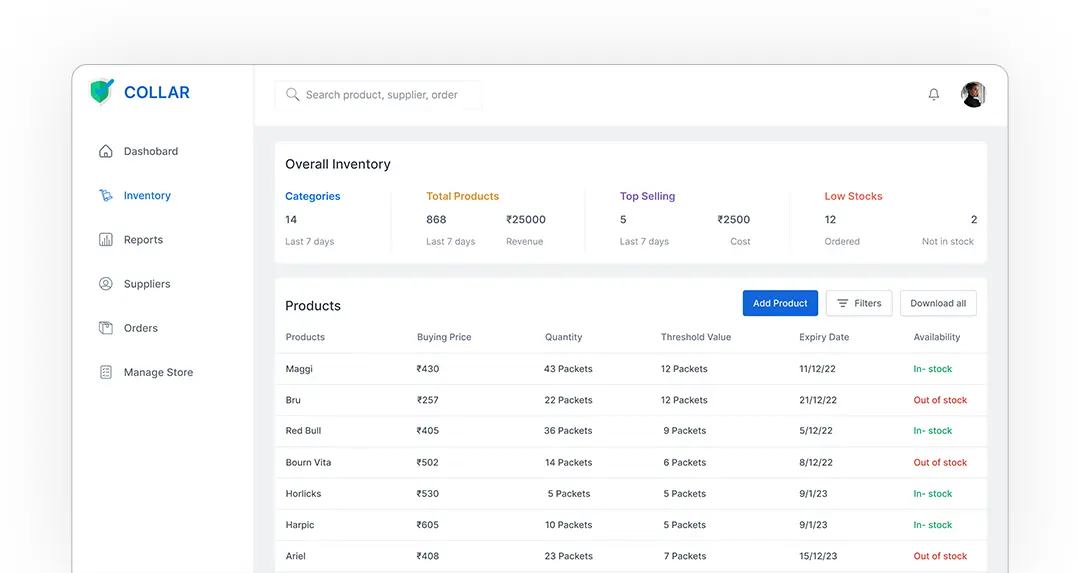

- Real-time Inventory Tracking: To monitor movement of the inventory from receipt to shipping in real-time; the Warehouse Inventory Management System used barcodes and RFID (Radio-Frequency Identification) technology. This completely avoided manual entry and ensured proper stock levels.

- Optimized Warehouse Layout: WIMS helped optimize warehouse layout based on product popularity and movement patterns which reduce travel time for picking and put-away.

- Automated Put-away and Picking: WIMS directed the warehouse staff to the most effective locations for both storing and retrieving items; reducing errors to the maximum while increasing productivity.

- Demand Forecasting: Historical sales data was used along with seasonal trends through WIMS. This helped make predictions about what the demand should be; keeping ABC Retail out of stock positions.

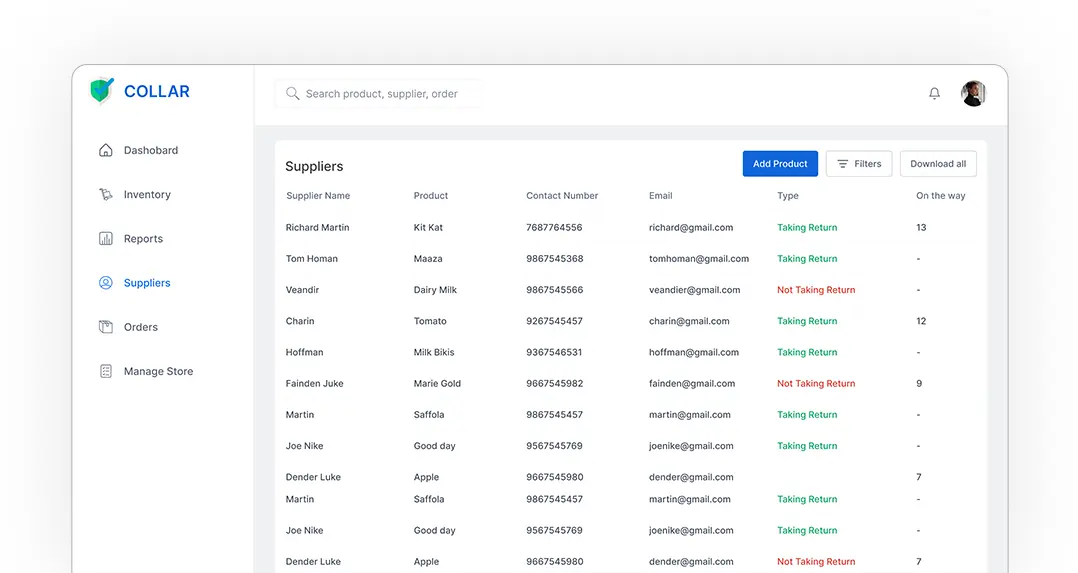

- Reporting: The system even produced a range of reports, including inventory levels, sales trends, and warehouse performance metrics.

- Integration with Other Systems: WIMS integrated flawlessly with ABC Retail's e-commerce platform and accounting system; making order processing and financial reporting easier.

Results of Warehouse Inventory Tracking System

The Warehouse Inventory Management System showed the following results for WIMS Retail:

- Improved Inventory Accuracy: The implementation of real-time tracking of the inventory has helped reduce the discrepancy by more than 95%, removing stockouts and overstocking.

- Warehouse Efficiency Increased: Optimization of warehouse layout and automation improved the efficiency of picking and putting away by approximately 30% which reduced the labour cost.

- Improved Order Fulfillment: Proper management of inventory and smooth functioning of the operation helped ABC Retail during the peak season. Thus delivered goods faster and ensured higher customer satisfaction.

- Better Decision Making: A real-time view of inventory stock and automatic report generation enabled the management to understand the requirements better for buying, pricing, and promotions.

- Overall Cost Reduction: The improved efficiency, fewer mistakes, and optimization of inventory brought down the general cost of the warehousing segment.

Technologies and Tools:

- Backend: Java, C#, Python, Node.js

- Frontend: HTML, CSS, JavaScript, React.js

- Database: MySQL

- Tools: Git, GitHub, GitLab, Docker

Are you Interested in Developing A Similar Warehouse Inventory Management System?

Our consultants are ready to hear your ideas. Request a free consultation with our software & app experts and transform it into a digital reality.